IC660ELB912G Network Interface Card

IC660ELB912G Network Interface Card

Product manual:

Main functions and features

Genius bus communication:

Provide seamless connection with Genius bus network for real-time data transmission and interaction of control signals.

Support network integration of multiple slave devices.

Modular interface:

Designed for GE Fanuc PLC systems and compatible with various industrial equipment.

Efficient data transmission:

Support high bandwidth industrial data communication to ensure response speed and data accuracy.

Durable design:

Industrial grade construction, earthquake resistant, heat-resistant, suitable for harsh environments.

Diagnostic function:

Provide status indication and fault diagnosis to facilitate monitoring of network operation status.

technical specifications

model: IC660ELB912G

Supported networks: Genius Bus communication protocol

Communication speed: typically 153.6 kbps (according to Genius network standards)

Maximum number of nodes: supports multiple nodes in Genius network

Power requirement: 24V DC or powered by the host (please refer to the product manual for specific requirements)

Working temperature:- 20 ° C to+60 ° C

Humidity range: 5% to 95% (without condensation)

Physical dimensions: Suitable for standard control cabinet installation

Weight: Approximately 0.5-1 kilogram

application area

Industrial automation:

Used for data communication and control between industrial field equipment.

Manufacturing control system:

Real time monitoring applied to automated production lines and manufacturing equipment.

Energy and Power Management:

Used for equipment communication in power plants and substations.

Process industry:

Provide support in complex control networks in industries such as chemical and pharmaceutical.

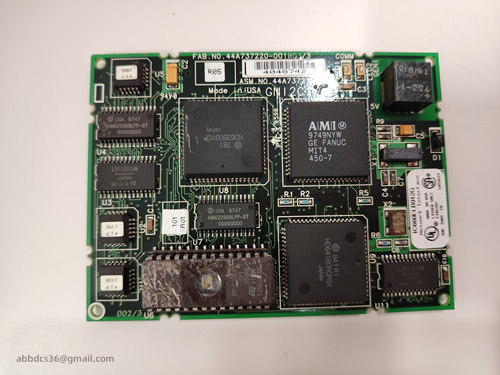

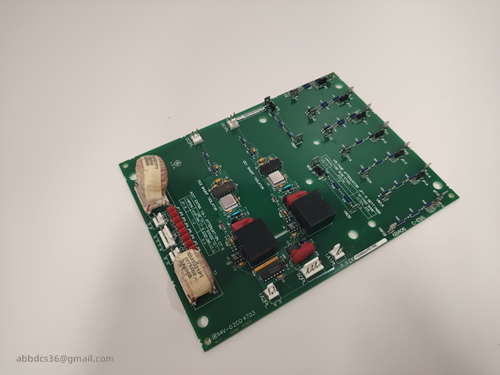

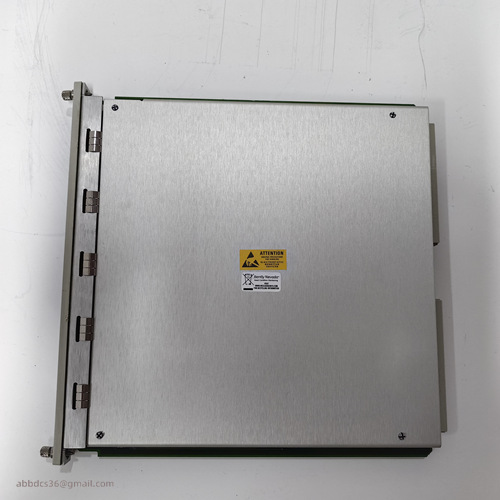

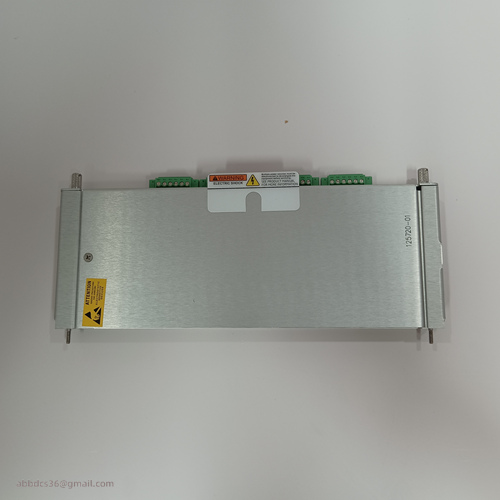

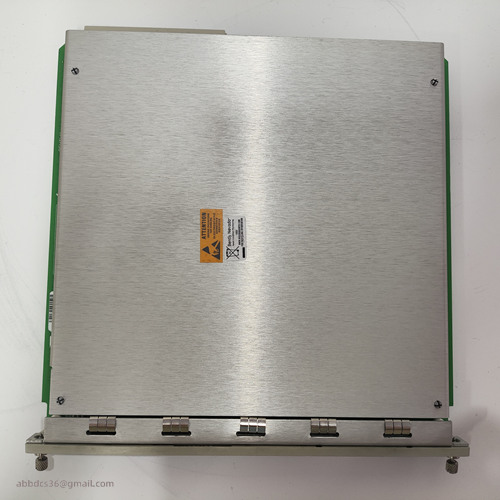

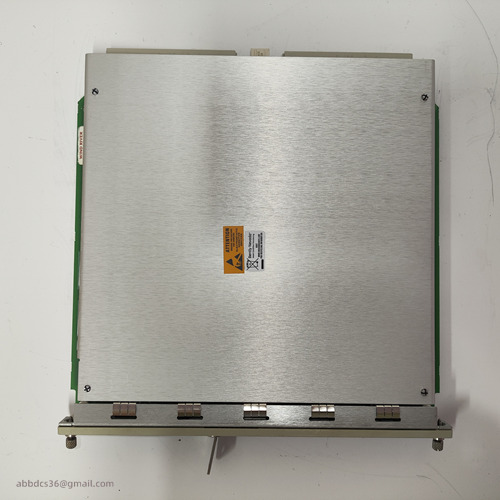

Product details picture:

GE 369-HI-R-M-0-0 Motor Management Relay: Advanced Protection for Industrial Motors