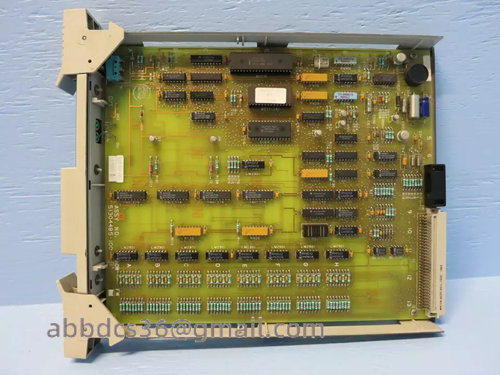

Honeywell 51304485-100 Digital Input Board

Product manual:

The Honeywell 51304485-100 digital input board is a key module in Honeywell industrial automation systems, designed to collect and process digital signals. It is an important component of process control and industrial monitoring systems, capable of efficiently receiving digital input signals from external devices and transmitting them to the control system, achieving precise process control and real-time monitoring.

Product Overview

Brand:

Honeywell

model:

51304485-100

Product type:

Digital Input Module

Function:

Receive external digital signals and transmit them to the control system

Support signal monitoring and status feedback

main features

High performance signal processing:

Support multi-channel digital signal input, fast response, ensuring system real-time performance.

Modular design:

Compact design facilitates installation, maintenance, and replacement.

Wide compatibility:

Compatible with Honeywell’s DCS systems (such as Expert PKS) and can also be integrated with other automation platforms.

Anti interference design:

Industrial grade anti-interference capability ensures stability in complex electromagnetic environments.

High reliability:

Support long-term stable operation in industrial environments.

Status indication function:

Equipped with LED or other forms of status indicators for real-time monitoring of module operation status.

technical specifications

Detailed parameter information

Input signal type: standard digital signal

Number of channels: Multiple channels (specific number can be determined according to system configuration)

The input voltage range usually supports 24V DC, depending on the configuration

Response time<1 ms, meeting high-speed control requirements

Working temperature range -20 ° C to+60 ° C

Storage temperature range -40 ° C to+85 ° C

Humidity range 5% to 95% (non condensing)

The protection level is usually IP20 or higher (depending on the installation environment configuration)

The communication interface supports seamless communication with the main control system

Installation method: Standard rack installation or module slot installation

Application scenarios

Process automation:

Receive switch signals from industrial field equipment (such as valve switch status, limit switches, etc.) for process control and monitoring.

Equipment monitoring:

Monitor the status of critical equipment, trigger alarms or initiate emergency response.

Production line control:

Implement digital signal input and real-time feedback for key links in the production line.

Electricity and Energy:

In power and energy management systems, it is used to collect switch signals from devices such as circuit breakers and relays.

Environmental monitoring:

Used in industrial waste gas and wastewater treatment systems to receive operational status signals from equipment.

Leave a comment

Your email address will not be published. Required fields are marked *