GE V7768-320001 Digital Output Module

GE V7768-320001 Digital Output Module

Product manual:

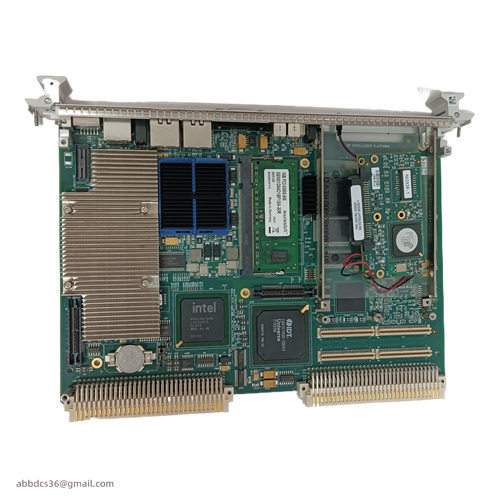

GE V7768-320001 is a digital output module,

Commonly used in industrial automation systems,

Used to convert the output signal of the control system into a digital signal and output it to actuators or other devices.

This module is typically part of GE digital control systems and has high reliability and precise control capabilities.

Main features:

Digital output: capable of providing multiple digital output channels, each channel used to control different devices or actuators.

High performance: usually has a fast response time, suitable for application scenarios that require real-time control.

Compatibility: Compatible with other automation equipment and systems from GE, integrated into larger control systems.

Industrial applications: widely used in industries such as factory automation, process control, and mechanical equipment.

Common applications:

Control digital input devices such as switches and relays.

Used for on-site equipment control in automation systems.

Can be integrated into PLC systems as part of external device control modules.

Product details picture:

GE 745-W2-P5-G5-HI-A-L-R: Advanced Transformer Protection System