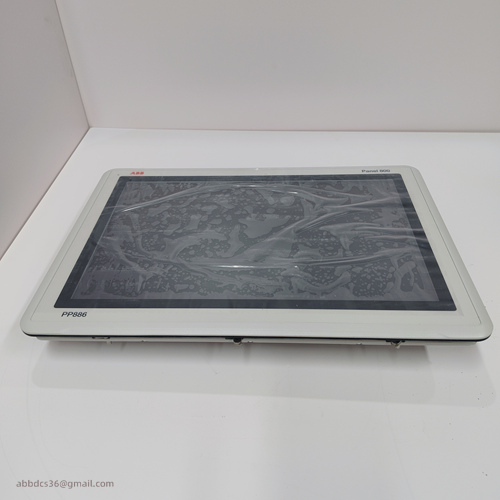

PP886 3BSE092980R1 Touch Screen Panel

PP886 3BSE092980R1 Touch Screen Panel

Product manual:

PP886 3BSE092980R1 is a touch screen panel produced by ABB,

Usually used in automation control systems as an interactive platform between the user interface and the operating system.

It provides operators with an intuitive graphical interface for monitoring and controlling industrial equipment and processes.

Main features:

Intuitive interface: Equipped with touch screen display function, users can easily view and control system parameters through touch operation interface.

High resolution display: providing clear graphics and data display,

Supports multiple language interfaces, making it convenient for operators in different regions to use.

Flexible configuration: Supports connection with various industrial automation control systems and can interact with devices such as PLC and DCS for data exchange.

Industrial grade design: resistant to high temperatures, waterproof, dustproof, and suitable for harsh conditions in industrial environments,

Ensure stable operation of equipment in harsh environments.

User friendly: Provides easy operation and graphical interface,

Reduced the learning time for complex operations and improved operational efficiency.

Application areas:

Industrial automation: Used as an operating interface for automation control systems, monitoring the status of production lines and equipment.

Process control: widely used in process control systems in fields such as petroleum, chemical, and power.

Equipment monitoring: Suitable for real-time monitoring and data input/output of various machines and devices, improving production efficiency and safety.

In short:

PP886 3BSE092980R1 touch screen panel is used for the operation and monitoring of industrial automation systems,

Provide a clear and intuitive interface to assist operators in real-time control and monitoring of equipment,

Widely used in various automation control and process monitoring systems.

Product details picture:

ABB PP886H 3BSE069297R1 – High Performance Industrial Control Module

ABB PP886 3BSE092980R1: Precision Function Key Panel for Industrial Control