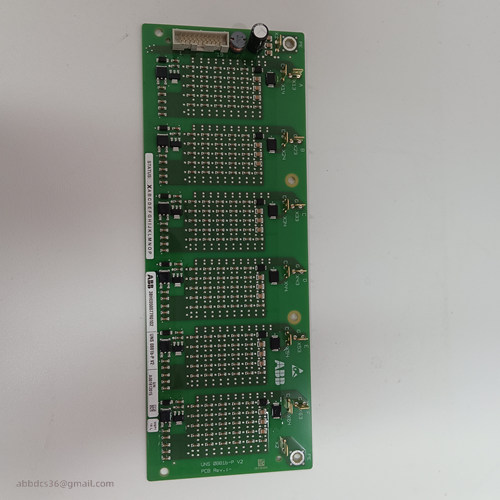

3BHE05077R0102 UNS0881b-PV2 power module

3BHE05077R0102 UNS0881b-PV2 power module

Product manual:

Main features:

Power output:

Voltage and current output: Provides stable DC or AC power output, suitable for automation equipment with different voltage requirements.

High efficiency: The module design has high energy efficiency, which can reduce energy waste and improve the overall operating efficiency of the system.

compatibility:

Compatible with other ABB automation products, easy to integrate into existing systems, widely used in various industrial control environments.

High reliability:

Adopting high-quality components and precise design to ensure long-term stable operation, adapting to electrical interference and temperature fluctuations in harsh industrial environments.

Compact design:

The compact design makes it easy to install and maintain, occupies less space, and is suitable for installation in distribution cabinets or control panels.

Application areas:

Industrial automation system:

Power modules are commonly used in automation control systems to provide stable power supply for PLCs (programmable logic controllers), sensors, actuators, etc.

Process control:

In process control systems in industries such as chemical, petroleum, and food processing, power modules ensure continuous and stable operation of instruments and control systems.

Machine vision system:

In machine vision and quality inspection systems, the power module provides power support for high-power cameras and processing units.

Production line control:

Widely used in production line control systems to provide continuous and reliable power for machinery and robots.

Energy Management:

Provide stable power in the energy management system to ensure stable operation under different loads and operating conditions.

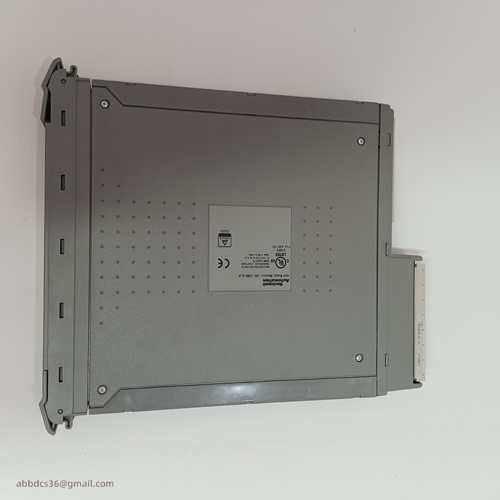

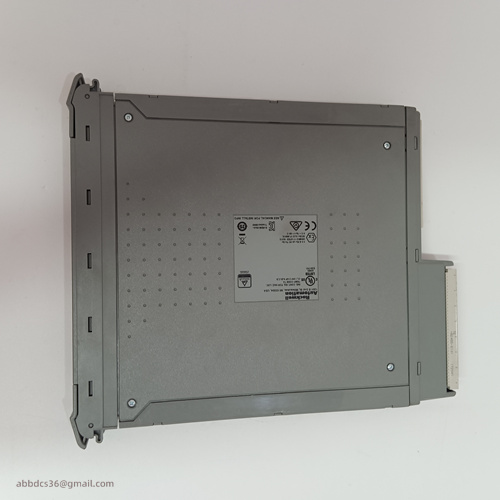

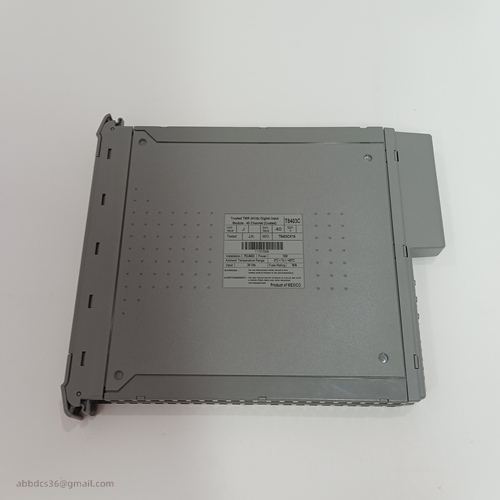

Product details picture:

ABB UN0824B-P V1: Advanced Industrial Control Module, Precision Designed for Automation Excellence