MITSUBISHI MR-S11-200-Z37 servo drive

MITSUBISHI MR-S11-200-Z37 servo drive

Product manual:

Main features:

Applicable models:

Driver type: Used to drive Mitsubishi Electric’s servo motors, supporting multiple specifications of servo motors.

Control mode: Supports position control, speed control, and torque control, and can flexibly respond to different application requirements.

Power and current specifications:

Rated output power: 200W

Rated current: It is related to the type of motor and usually ranges from a few amperes. The specific parameters need to be determined according to the matched motor model.

Control method:

Support vector control, which can provide high-precision positioning control and smooth speed control.

Adopting PWM modulation technology to ensure efficient energy conversion and stable operational performance.

Communication interface:

It supports multiple communication protocols, such as CC Link and Modbus, making it easy to integrate with other control systems, PLCs, and other devices.

Security and protection functions:

Built in overload, over temperature, over voltage, under voltage and other protection functions ensure the stable operation of the equipment in various complex environments.

Support emergency stop and automatic recovery functions to improve system reliability.

Operating environment:

The working temperature range is usually from 0 ° C to 40 ° C, suitable for most industrial environments.

Dustproof and waterproof design enables it to work in relatively harsh environments.

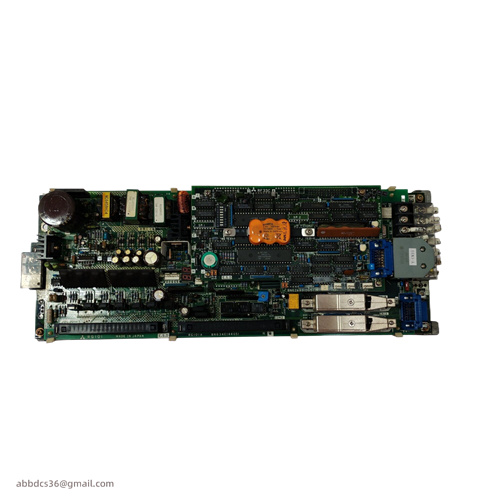

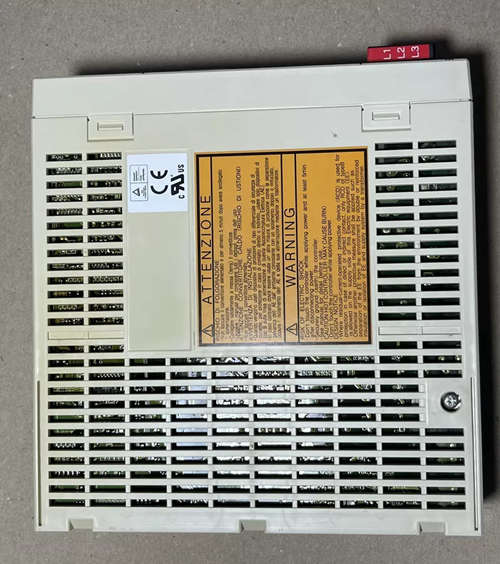

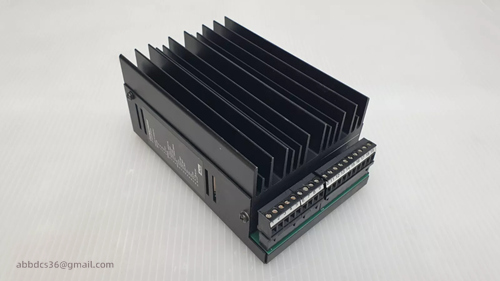

Product details picture:

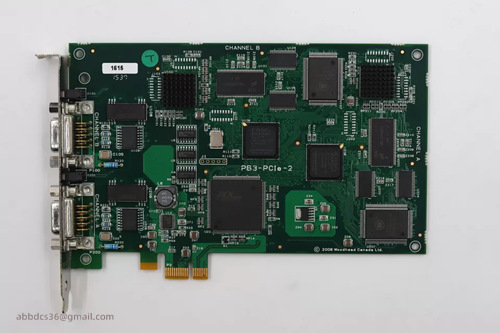

Mitsubishi A2NCPU-UL Melsec-A Programmable Controller, Advanced Control Solution

Mitsubishi FX2N-32MR Programmable Controller, Industrial Automation