Measurement Range:±15,000 RPM

Accuracy:±1% of full scale

Operating Temperature:-40°C to +70°C

Operating Humidity:0% to 95% non-condensing

Power Supply:9 to 30 VDC, 100 mA

Communication Interface:RS-485 Modbus RTU

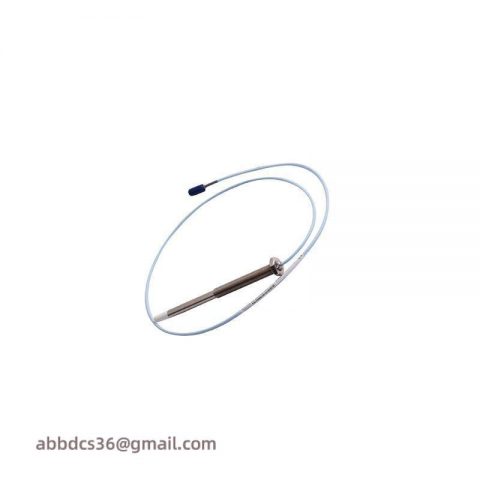

The Bently Nevada 3500 Vibration Monitoring System is engineered for precision, featuring high-resolution sensors that accurately capture machinery vibrations within a wide frequency range. This system is pivotal in condition-based maintenance, providing immediate insights into the health status of industrial equipment.

Designed with advanced algorithms, the system analyzes real-time data to predict potential failures before they occur, significantly reducing the risk of unplanned shutdowns and minimizing maintenance costs. Its versatile input types—accelerometers, velocity sensors, and displacement transducers—ensure compatibility with a broad spectrum of machinery.

For enhanced usability and integration, the Bently Nevada 3500 offers multiple communication protocols, including RS-485, Ethernet, and OPC-UA, facilitating seamless connectivity with various industrial control systems. Its robust power supply adapts to diverse environments, ensuring reliable operation under varying conditions.

In terms of environmental tolerance, the system is built to withstand temperatures ranging from -20°C to +60°C, making it suitable for use in extreme industrial settings. Its compact design allows for easy installation and integration into existing machinery without compromising functionality.

With comprehensive data logging capabilities, the Bently Nevada 3500 enables users to monitor historical trends and make informed decisions about maintenance schedules, optimizing production uptime and ensuring safety standards are met. This system is an indispensable tool for modern industries seeking to enhance reliability and efficiency through proactive maintenance strategies.

There are no reviews yet.