Control Architecture:Modern PLC-based

Input Capacity:Up to 500 inputs

Output Capacity:Up to 300 outputs

Communication Protocols:Supports Modbus, CAN, Ethernet

Operating Temperature:-20°C to +55°C

Power Consumption:Max 200W

Memory:2MB Flash, 1MB RAM

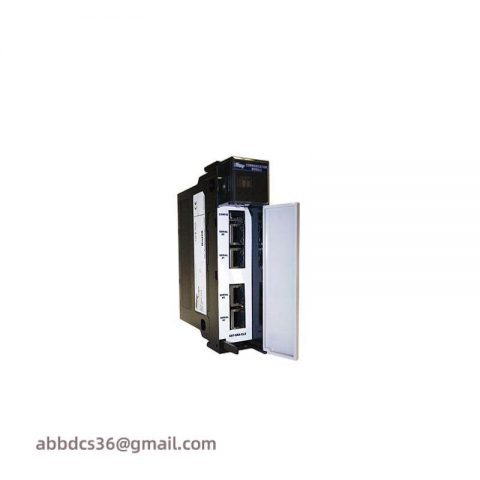

Engineered with cutting-edge technology, the Durant 5882-1 Industrial Process Control Module is designed for optimal performance in challenging industrial environments. Its compact design ensures easy integration into existing systems without compromising on functionality or efficiency.

Featuring an advanced sensor interface, this module supports a wide range of sensors and actuators, enabling precise control over critical parameters such as temperature, pressure, and flow rates in diverse applications including chemical processing, manufacturing, and environmental monitoring.

Equipped with robust communication protocols, it seamlessly connects with other devices and systems, facilitating real-time data exchange and control, thus enhancing operational efficiency and reducing downtime.

Built with durability in mind, the module withstands extreme temperatures and humidity conditions, ensuring reliable operation in harsh industrial settings. Its low power consumption makes it suitable for energy-conscious operations, minimizing operational costs.

Offering exceptional accuracy and quick response times, the Durant 5882-1 ensures consistent and precise control, contributing significantly to improved product quality and process reliability. It’s the ideal choice for engineers seeking a dependable and high-performance solution for their industrial control needs.

There are no reviews yet.