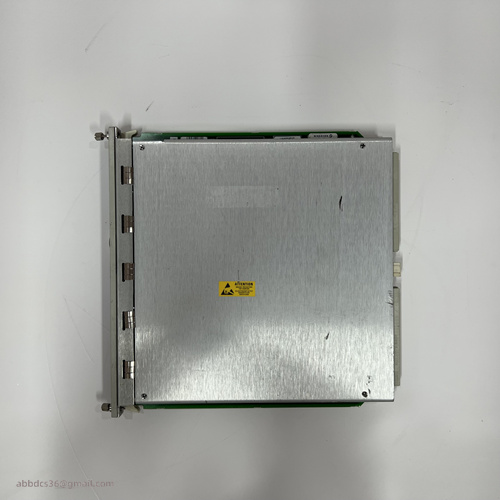

BENTLY 3500/22M 138607-01V Transient Data Interface Module

BENTLY 3500/22M 138607-01V Transient Data Interface Module

Product manual:

Main features:

Transient data collection: This module can efficiently collect transient data, which is crucial for monitoring the state changes of mechanical equipment during startup, shutdown, or failure.

Real time monitoring: provides real-time health assessment of mechanical equipment, promptly detecting potential faults or performance degradation.

High precision analysis: supports high-precision data collection and analysis, which helps with early fault detection and equipment maintenance.

Multi channel design: capable of monitoring multiple sensor inputs simultaneously, suitable for complex industrial environments.

Technical specifications:

Input type: Supports multiple sensor inputs, including accelerometers, velocity sensors, displacement sensors, etc.

Data processing capability: able to handle transient signals and quickly respond to instantaneous changes in equipment, such as shocks, vibrations, etc.

Compatibility: Compatible with other monitoring systems and software from Bently Nevada, seamlessly integrated into existing monitoring networks.

Environmental adaptability: Adapt to extreme industrial environments, including high temperature, high humidity, vibration, and electromagnetic interference.

Application areas:

Mechanical health monitoring: widely used for health monitoring of rotating machinery, pumps, fans, compressors and other equipment.

Predictive maintenance: By analyzing transient data, predictive maintenance can be performed to detect potential equipment failures in advance and reduce downtime.

Energy industry: Applied in power plants and the oil and gas industry to monitor the operating status of large rotating machinery and equipment.

Product details picture:

GE IS200AEADH1ABA – Precision Engineered Speedtronic Turbine Control PCB Board

GE IS200TBCIH1BCD: High-Performance Terminal Circuit Board for Industrial Control Systems